Sidewinder

Software Overview

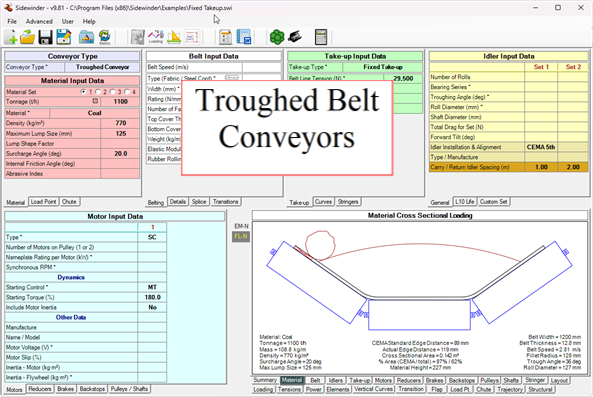

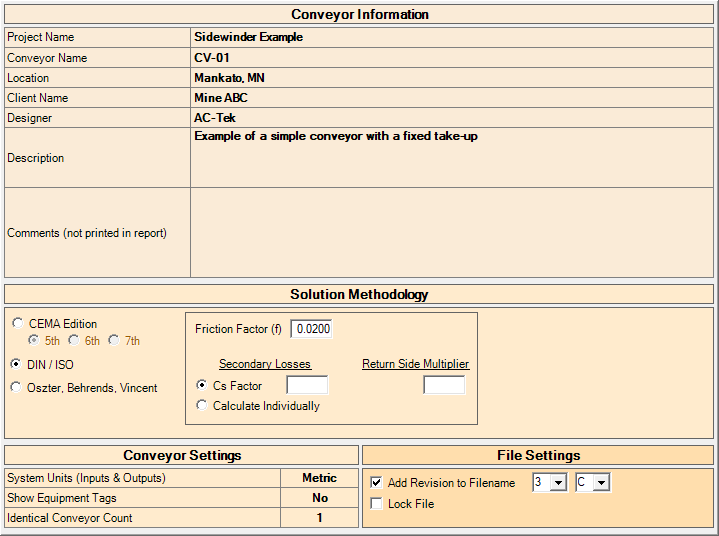

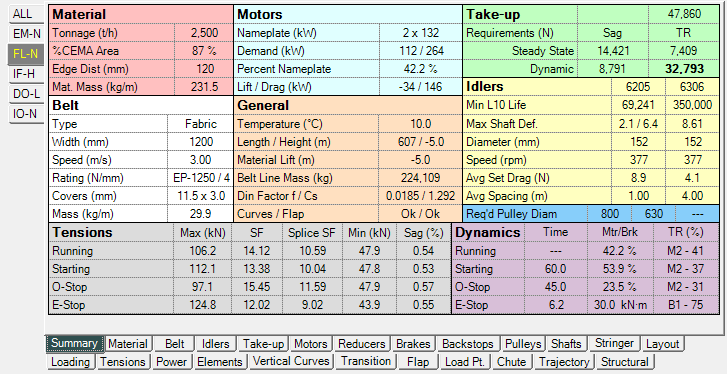

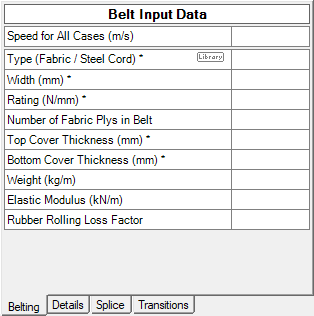

Sidewinder was developed from the ground up using the latest software development tools and years of conveyor design experience. The user interface and hierarchical structure was thoroughly laid out before development began. This resulted in a flexible program that can easily be upgraded with new features and technology in the future.

Some major features include:

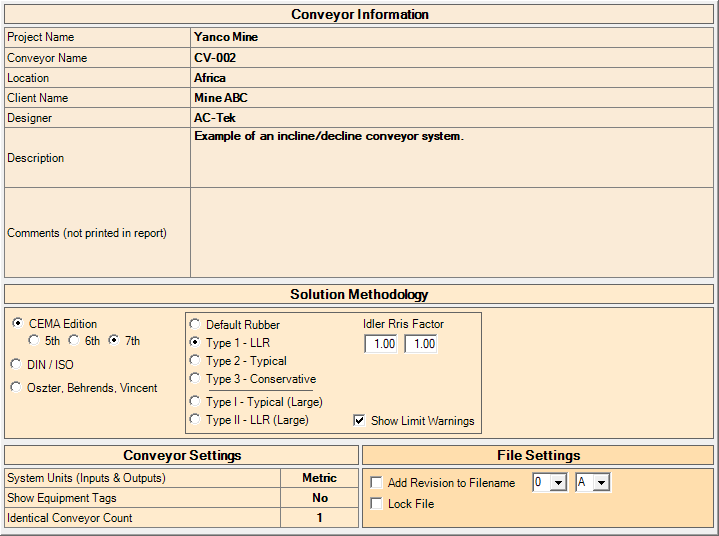

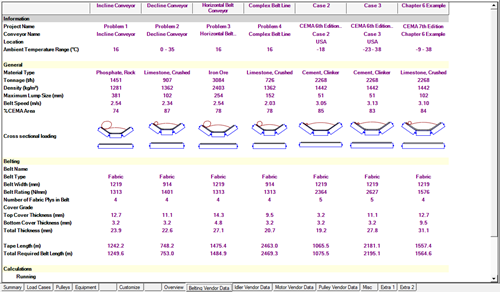

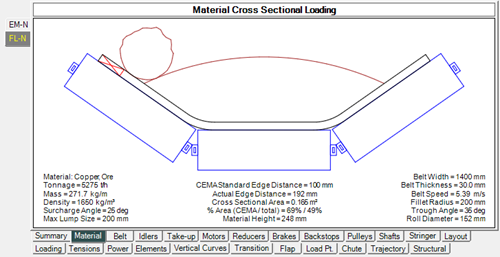

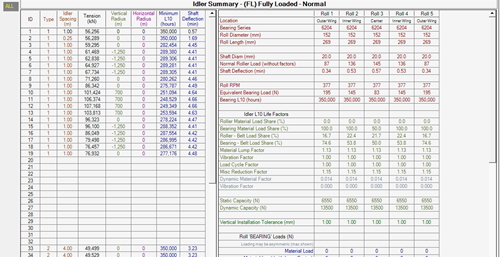

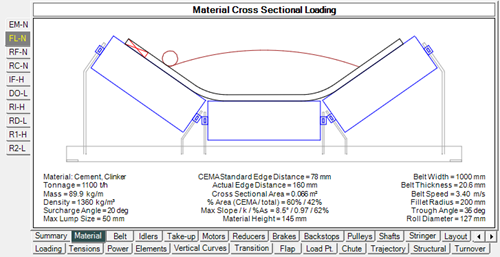

• CEMA 5th, 6th, and 7th edition, DIN 22101, ISO, and other calculation methodologies

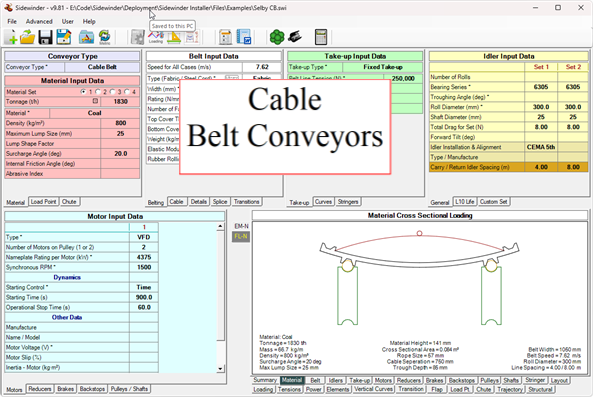

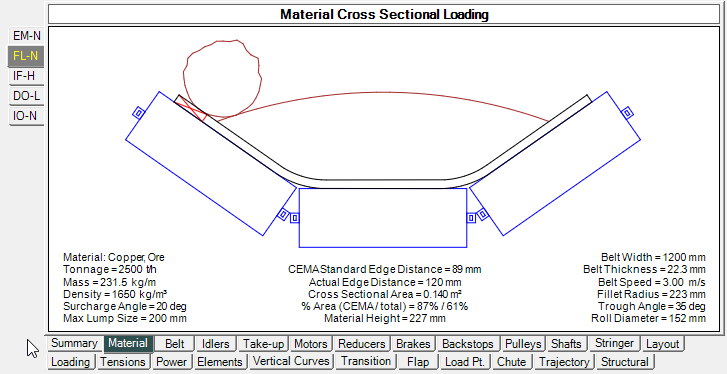

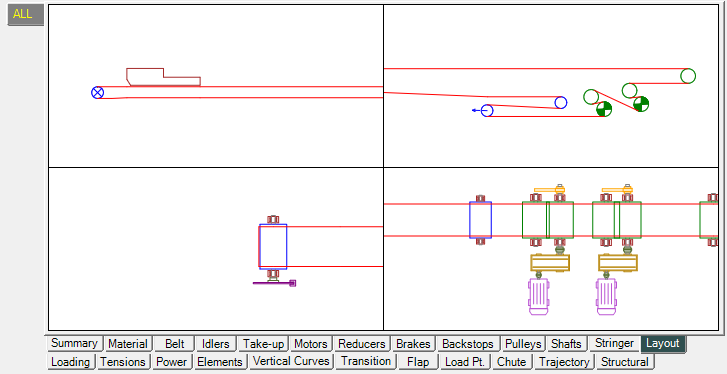

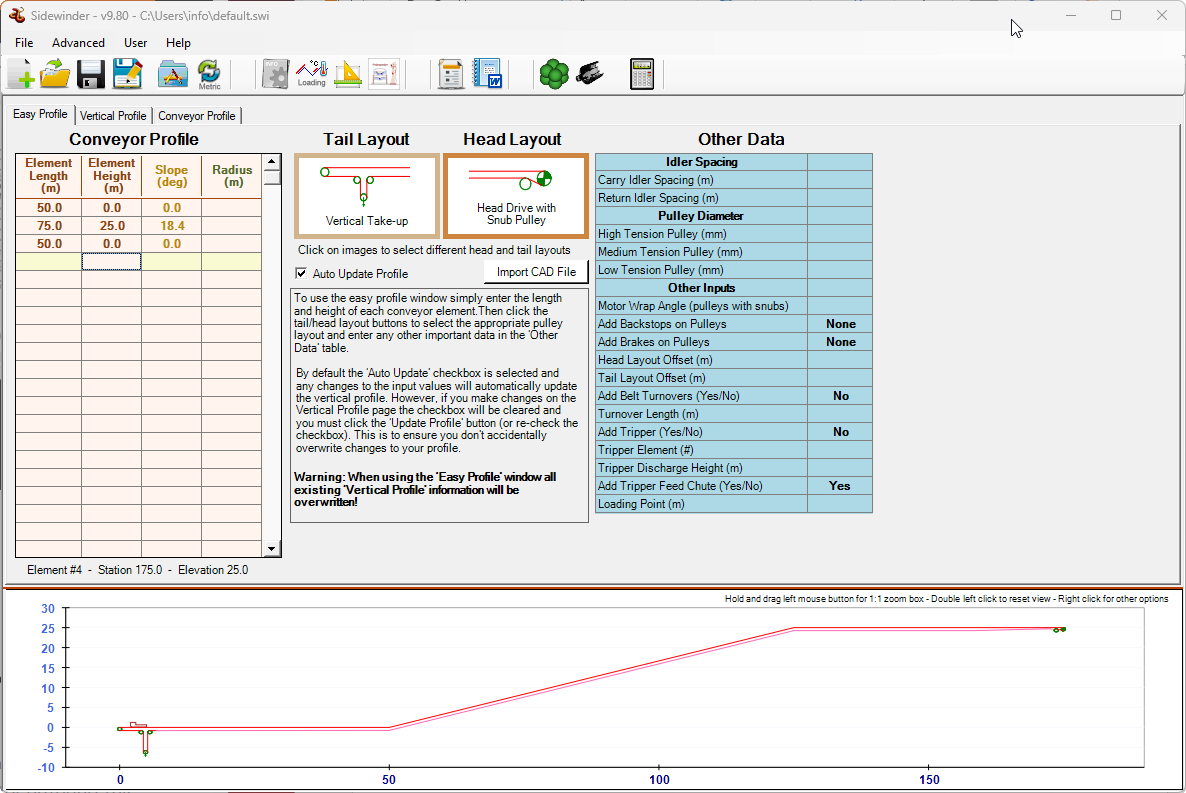

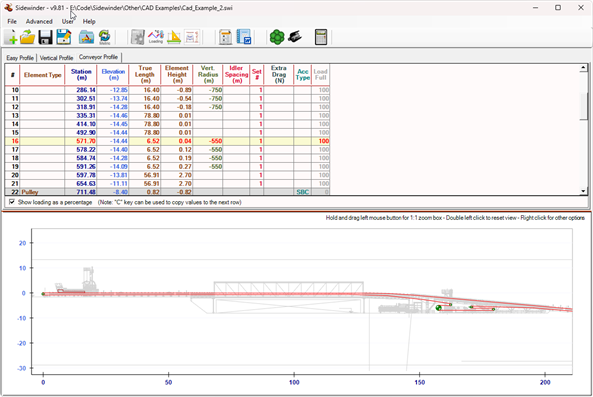

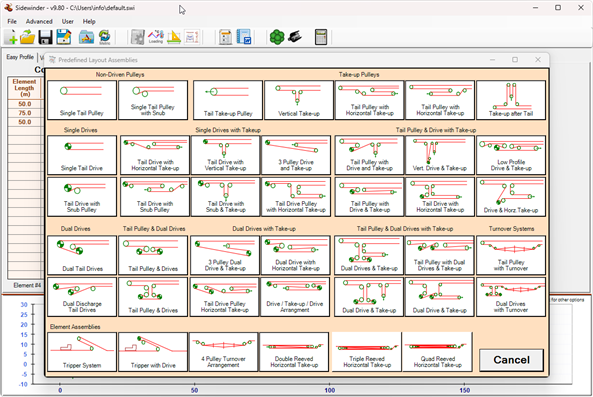

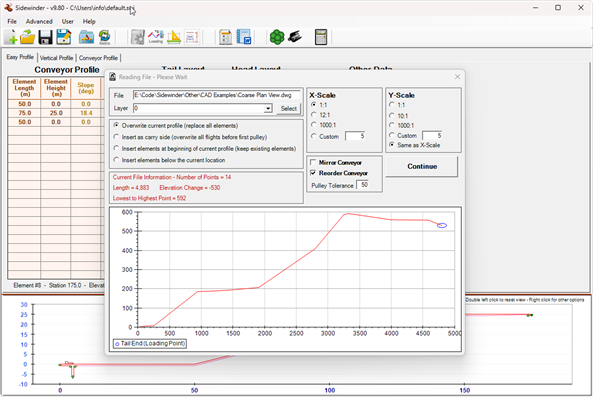

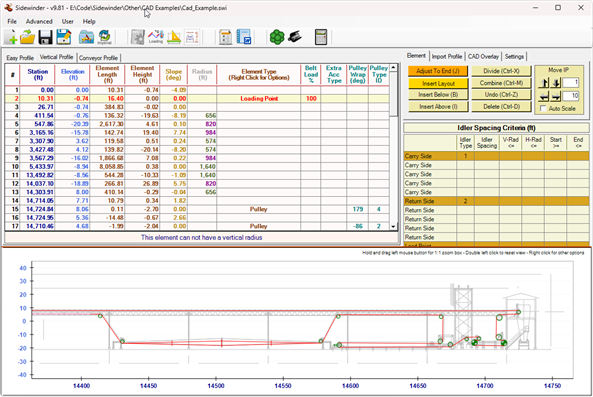

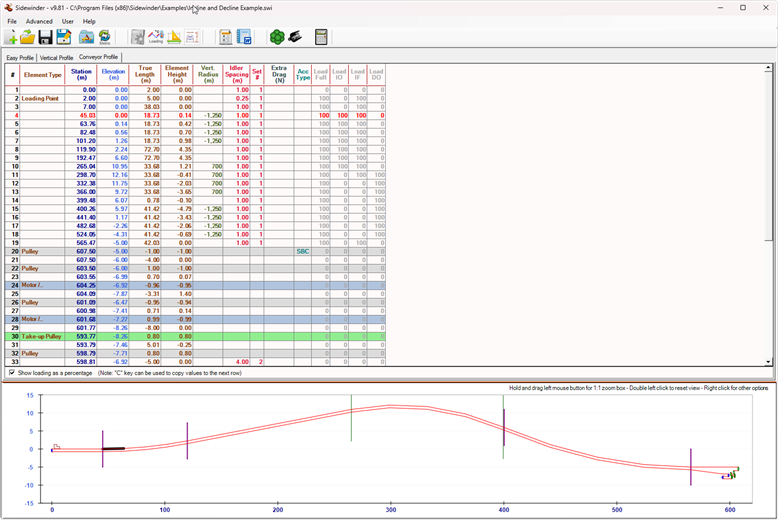

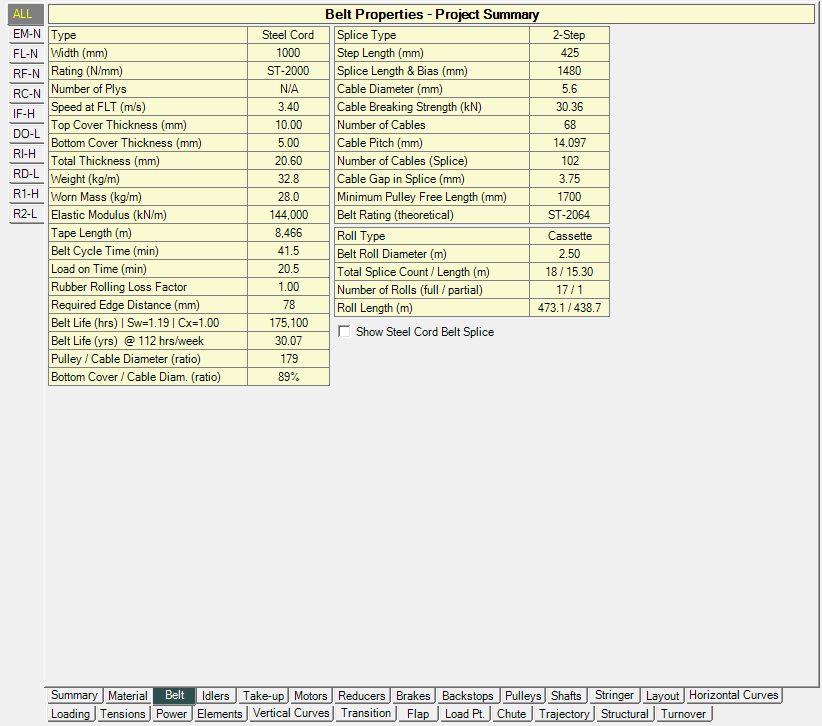

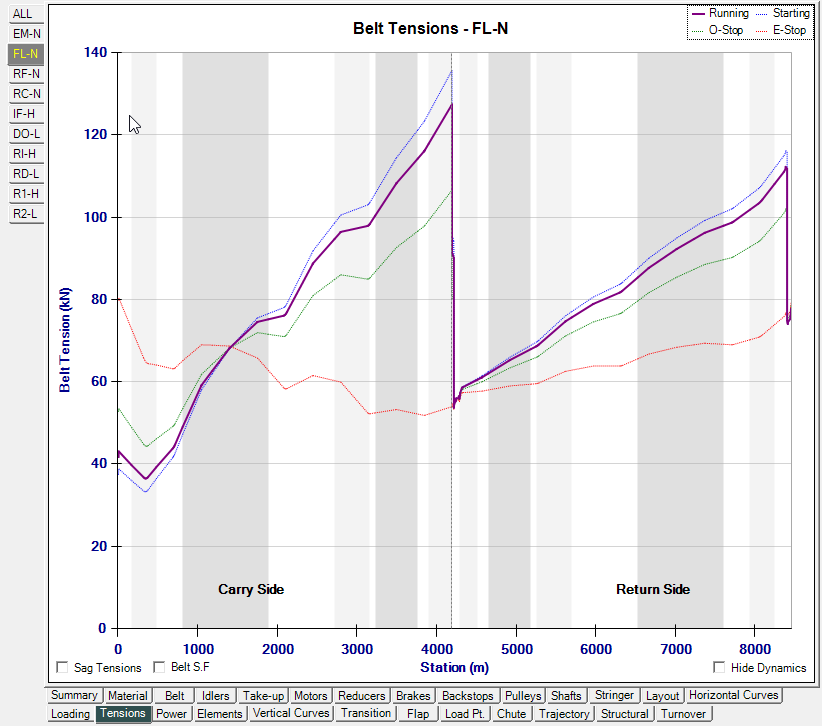

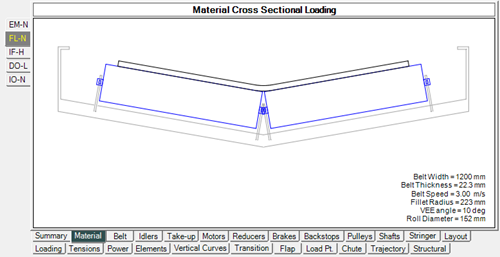

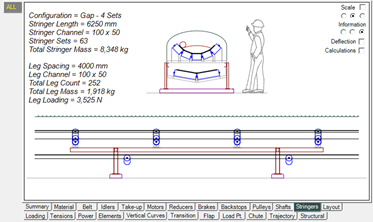

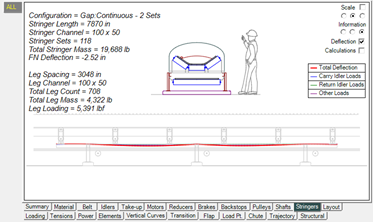

• Conveyors of any geometry, length, and drive configuration

• Quick Geometry Input

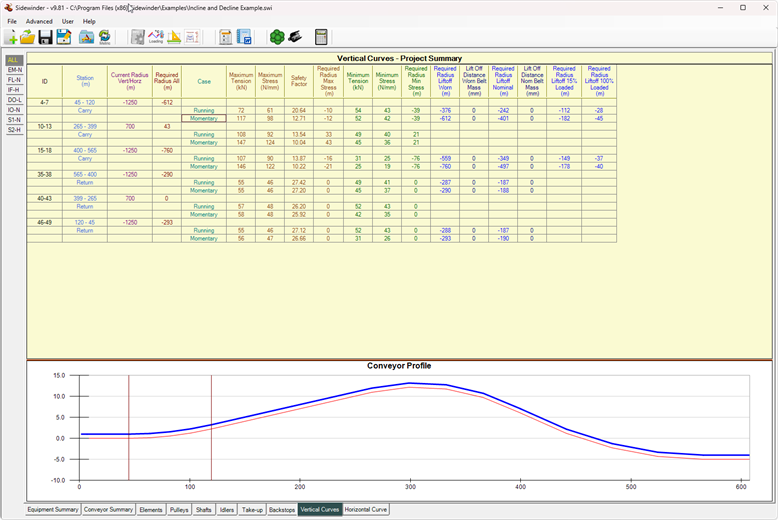

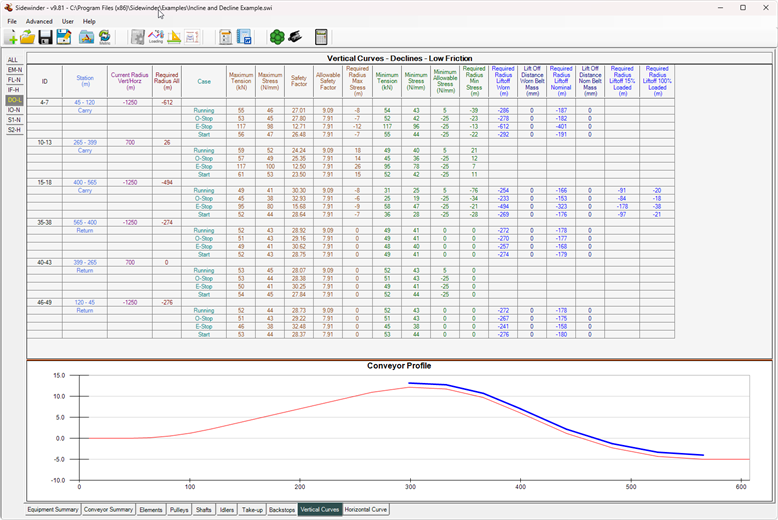

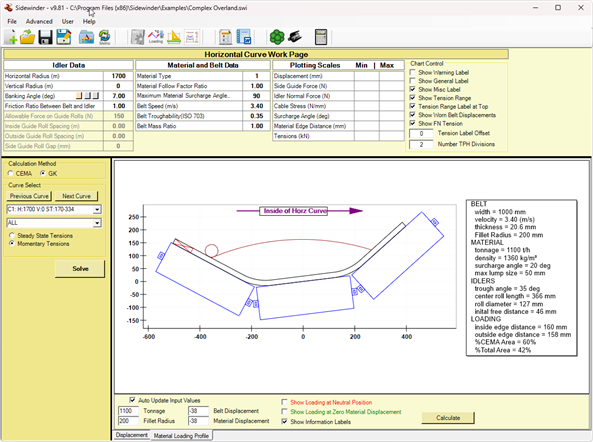

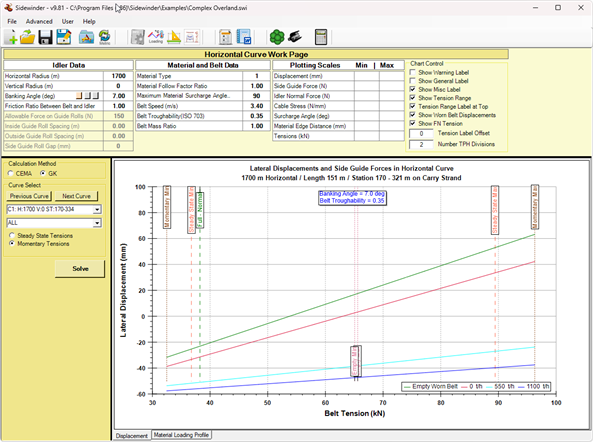

• Vertical and Horizontal Curve Analysis

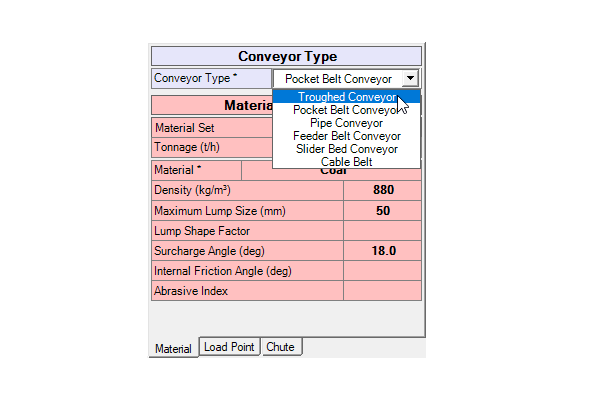

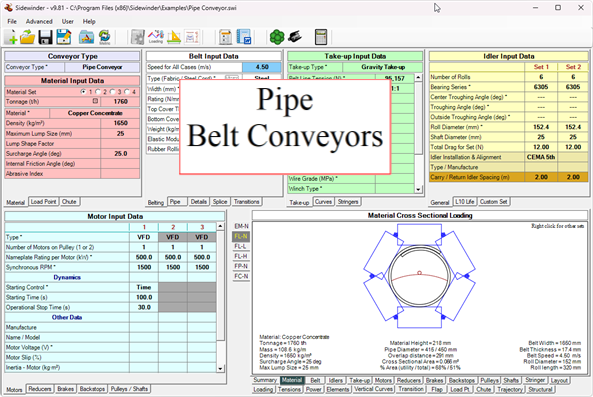

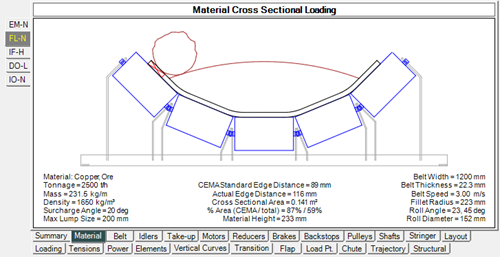

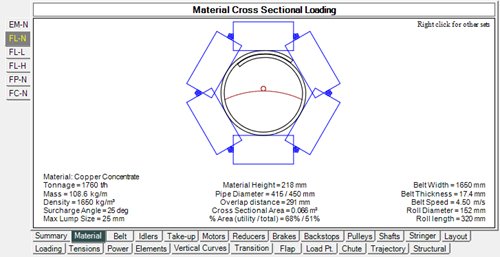

• Pipe conveyor calculations

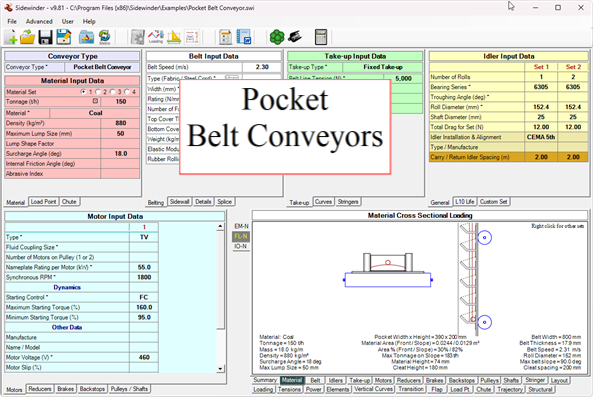

• Pocket / Flexowall Belt conveyors

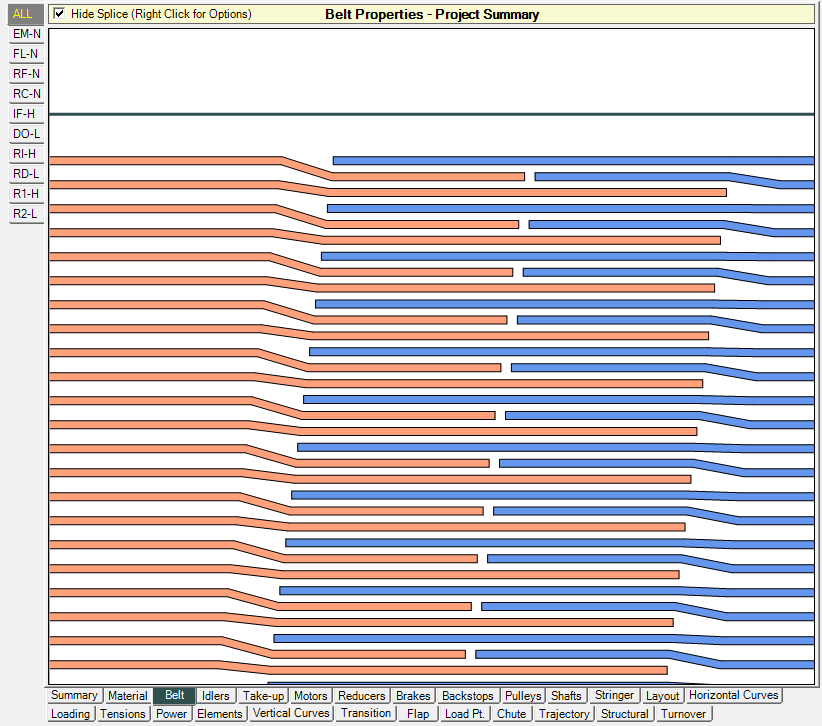

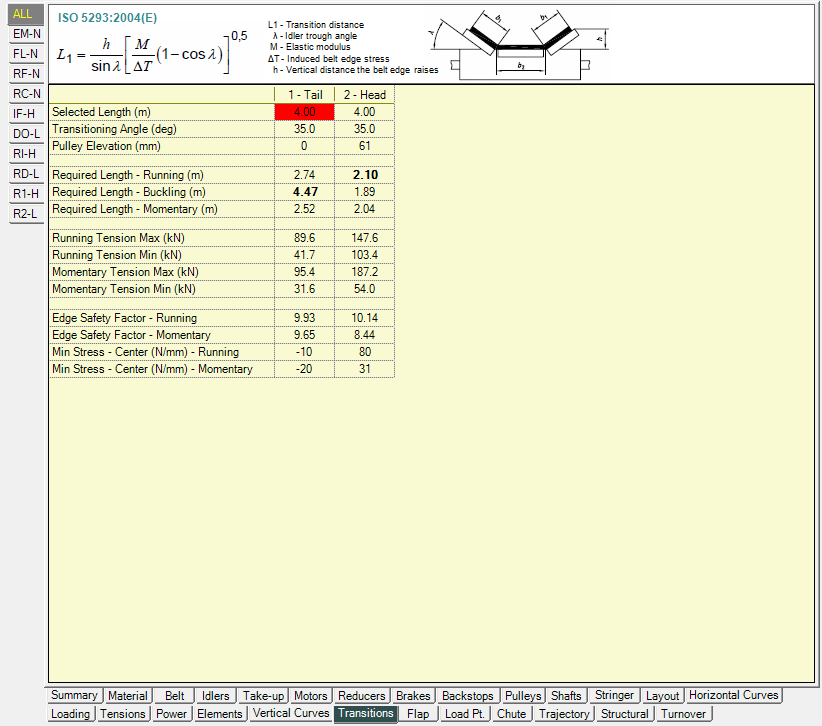

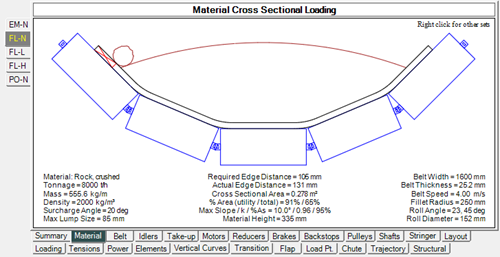

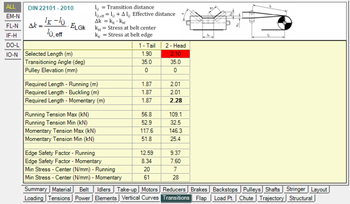

• Belt Transitions (CEMA, ISO, and the Beckley methods)

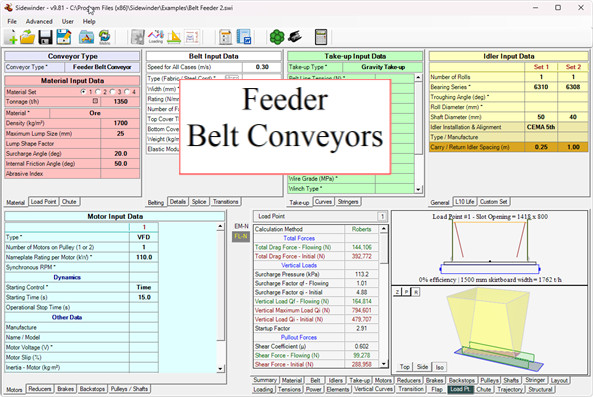

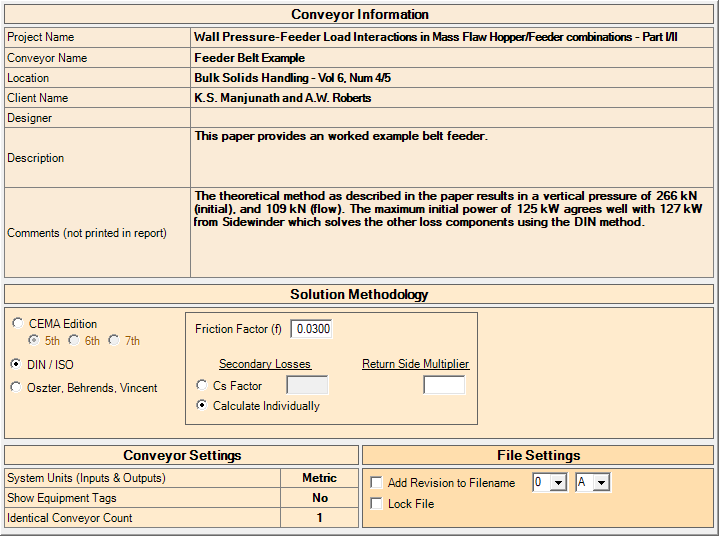

• Feeder Belt and pullout force calculations (CEMA, Roberts, Bruff's, Reisner, and Johanson methods are all included)

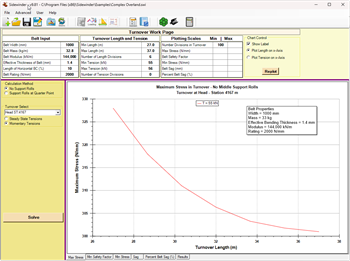

• Belt Turnover Calculations

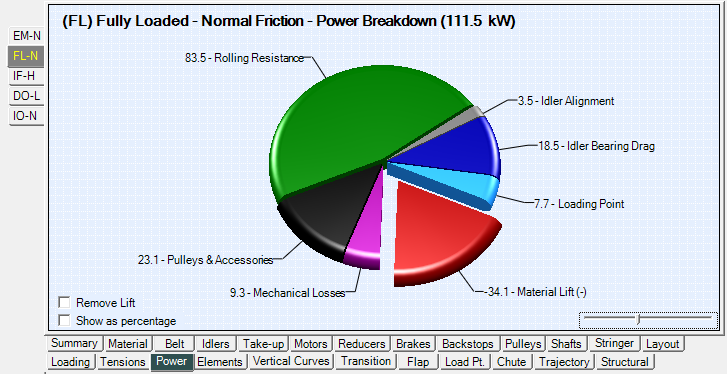

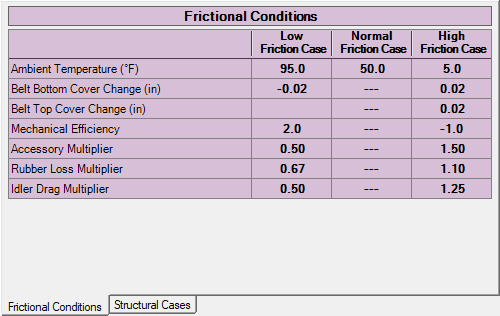

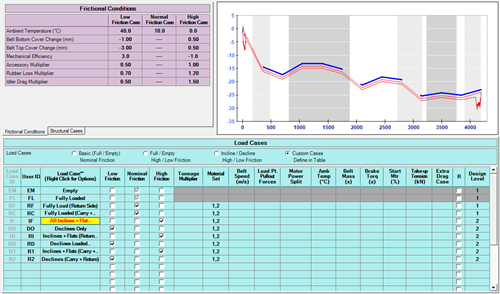

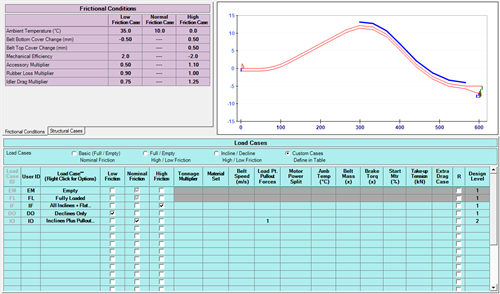

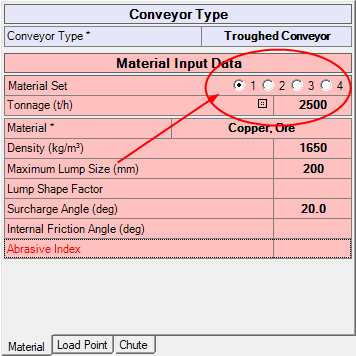

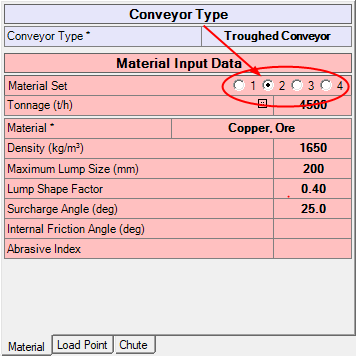

• Multiple load cases (inclines, declines, load on/off, custom cases, etc)

• Reversible conveyors and bi-way conveying (material on both carry and return sides)

• Multiple material types (up to 5 different material types and/or properties can be analyzed on a conveyor)

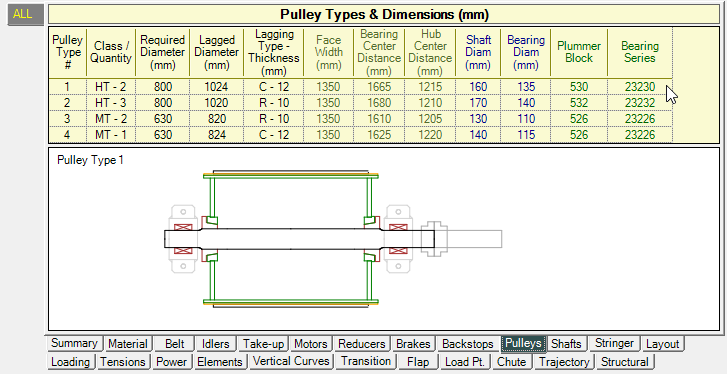

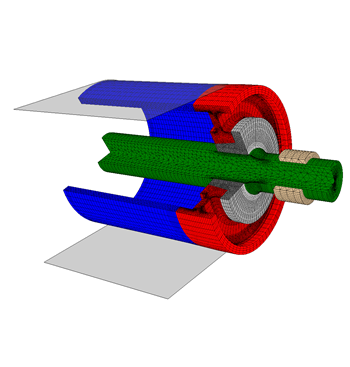

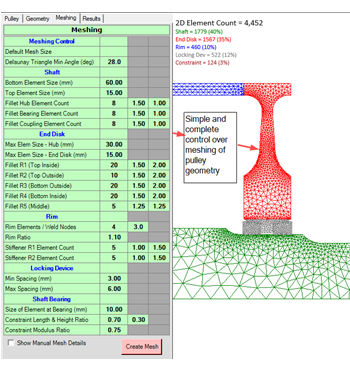

• Complete pulley and shaft sizing (both CEMA, AS-1430 methods)

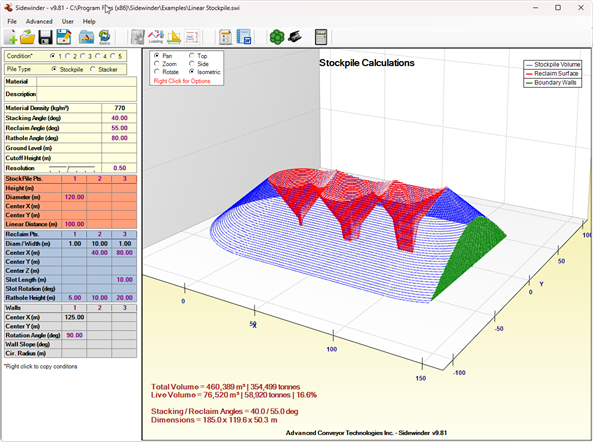

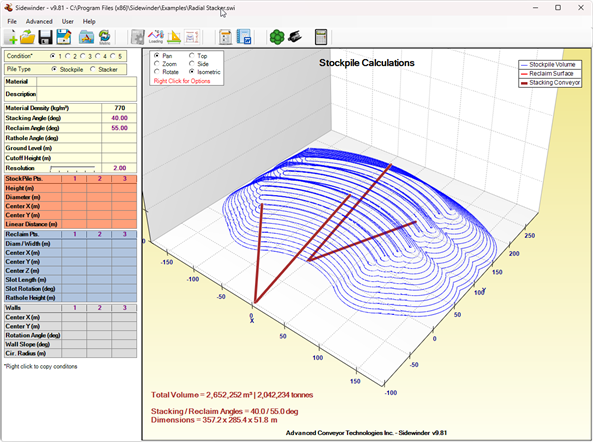

• Conical & Radial Stockpile Sizing and Reclaim Volume Calculations

• Professional reports (in Microsoft Word format)

• English & Metric Units

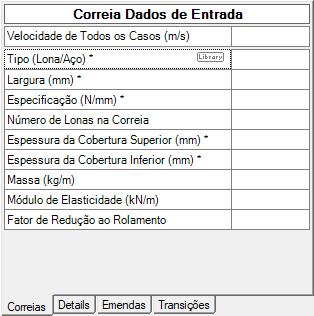

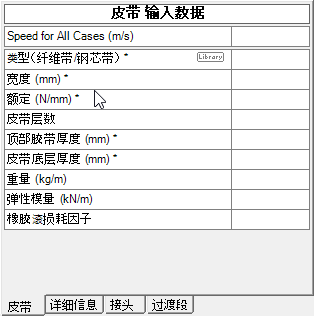

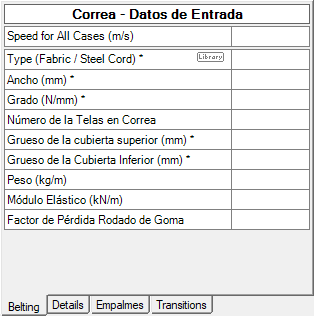

• Multiple Languages - Inputs & Outputs (English, Spanish, Portuguese, Italian, Chinese, German, and more)

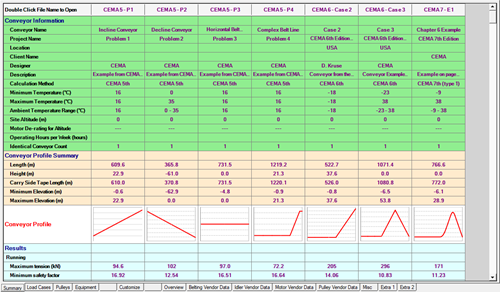

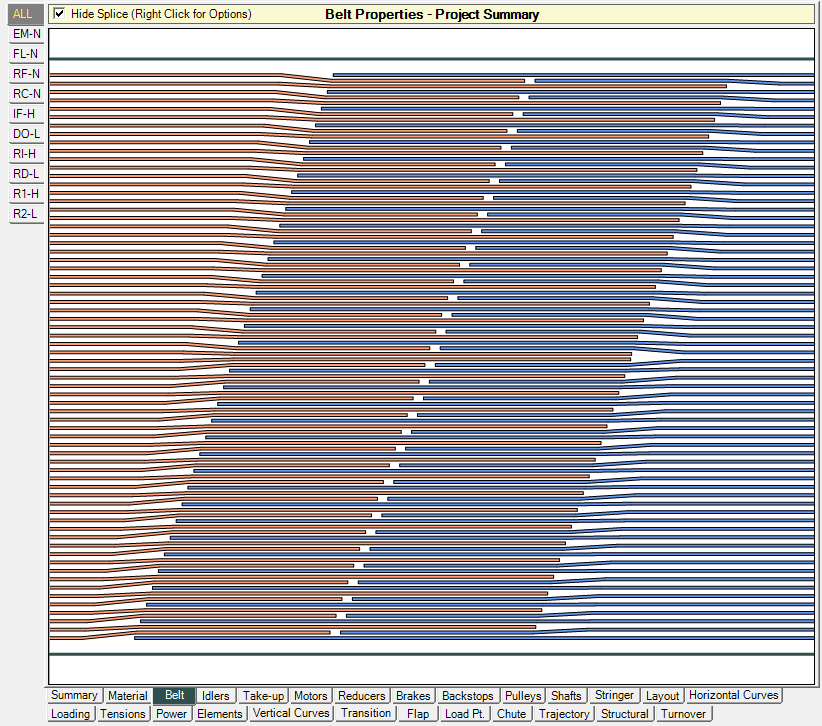

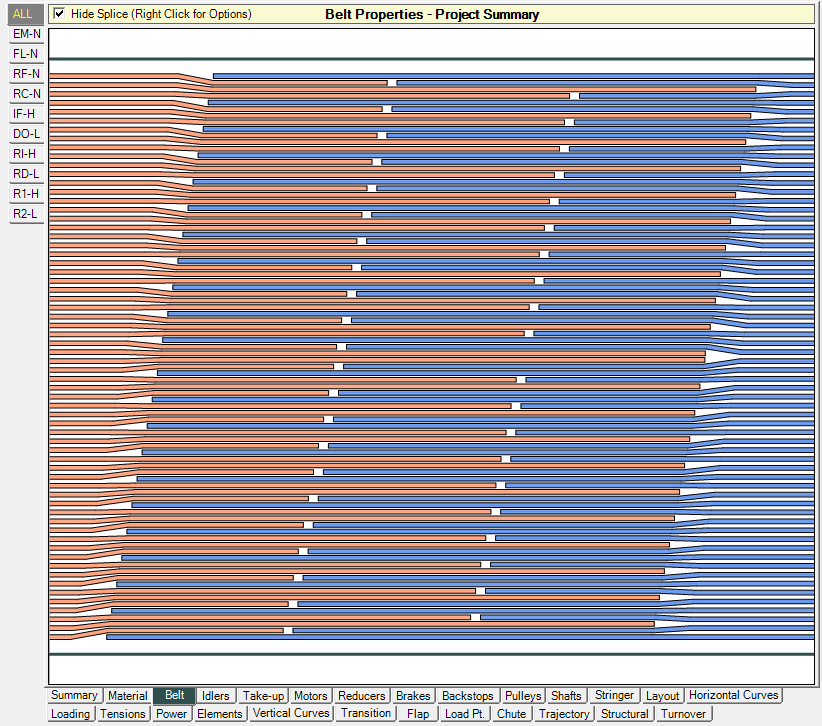

• Project summary files & report analysis for multiple conveyors in a single project

…..and much, much more….